Aluminum casting for automotive solutions that require strength and lightness

Wiki Article

Exploring the Function of Shop Solutions in Advancing Modern Design Solutions

Foundry services are vital in forming modern design services - Precision aluminum casting. They connect the void in between standard production techniques and the needs of contemporary sectors. With advancements in automation and sustainability, factories are evolving to fulfill the demands of markets such as aerospace and vehicle. This makeover elevates inquiries about the implications for materials, processes, and future technologies. What possibilities and obstacles lie ahead for factory services in this quickly changing landscape?The Development of Foundry Solutions in Engineering

The combination of computer-aided style (CAD) and simulation software program has actually revolutionized the layout and manufacturing processes, enabling shops to generate complicated geometries with greater precision. Additionally, the shift in the direction of green techniques has led to the fostering of greener technologies and recycling initiatives within factories. As markets progressively prioritize modification and rapid prototyping, shop services have expanded their capabilities, ensuring they stay important factors to the engineering landscape. This advancement emphasizes the factory's critical function in supporting innovations throughout different sectors, consisting of automobile, aerospace, and power.

Secret Processes and Methods in Modern Foundries

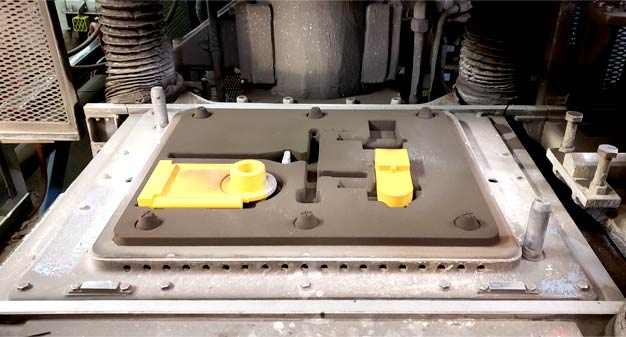

Modern factories use a selection of essential processes and strategies that enhance the performance and quality of metal spreading. Amongst these, sand spreading remains common because of its flexibility and cost-effectiveness. Making use of innovative innovations, such as computer-aided layout (CAD) and computer-aided production (WEB CAM), allows for exact modeling and manufacturing, making sure high accuracy in part measurements. Additionally, financial investment casting is preferred for generating complicated geometries with outstanding surface area coatings.Additionally, automation and robotics boost manufacturing speed and consistency while minimizing labor costs. Methods like additive manufacturing are significantly integrated to create intricate molds and cores, therefore decreasing material waste. The application of thermal analysis help in maximizing casting processes by regulating and predicting solidification behavior. Collectively, these strategies and processes exemplify just how modern-day factories are adjusting to fulfill the demands of modern design challenges, making certain premium product high quality and functional effectiveness.

The Relevance of Products Choice in Factory Providers

Selecting the proper materials is vital in factory services, as it straight influences the mechanical buildings, toughness, and overall performance of the final item. Various products possess one-of-a-kind qualities, such as tensile strength, rust resistance, and thermal security, which have to straighten with the designated application of the cast elements. As an example, steels like light weight aluminum and steel are frequently selected for their strength-to-weight proportion, while alloys can boost particular performance traits.Additionally, the option process entails considering factors such as manufacturability, price, and availability, which can notably influence job timelines and budgets. Additionally, improvements in product scientific research make it possible for the advancement of innovative composites and specialized alloys that accommodate emerging engineering difficulties. A comprehensive understanding of material properties and their effects is vital for designers and factory experts to attain effective results in their jobs. This careful option process eventually enhances the reliability and efficiency of completion products.

Shop Providers in Aerospace and Automotive Applications

Factory solutions play an essential duty in the aerospace and auto industries, where accuracy and performance are critical. These sectors depend heavily on the production of complicated elements that need to fulfill extensive quality requirements and stand up to severe problems. Factories give crucial services such as spreading, machining, and ending up, making certain components are light-weight yet robust, vital for improving fuel efficiency and security.In aerospace, factory services contribute to the manufacturing of wind turbine blades, engine elements, and architectural parts, all of which need intricate layouts and high-performance products. In a similar way, in the automotive industry, factories supply engine blocks, chassis components, and transmission cases, concentrating on toughness and weight decrease.

Advanced foundry strategies, including additive manufacturing and accuracy casting, are progressively used to satisfy the particular needs of these sectors. By providing customized remedies, shop solutions assist drive innovation and maintain competitive benefits in the fast-evolving aerospace and automobile landscapes.

Innovations Driven by Factory Capabilities

Various innovations in design are sustained by the advanced capabilities of factory solutions. These services enable the production of complicated geometries and high-performance materials that are important for modern-day applications. Additive manufacturing, frequently understood as 3D printing, has actually seen substantial improvements via factory strategies, enabling for the rapid prototyping of detailed designs. Additionally, the ability to cast lightweight alloys has revolutionized sectors such as aerospace and auto, causing boosted fuel performance and efficiency.Foundries are significantly integrating smart modern technologies, such as automation and data analytics, to boost manufacturing performance and high quality control. These advancements not just decrease waste however likewise allow customization at range, satisfying the particular needs of customers. By leveraging sophisticated shop capabilities, designers can check out new frontiers in item design and capability, inevitably driving progress throughout numerous sectors and establishing a foundation for future developments.

Future Fads in Foundry Providers and Engineering Solutions

The future of shop services is formed by arising trends such as sustainable production methods, which prioritize environmental duty. Automation and clever modern technologies are set to boost performance and accuracy, while raising personalization and versatility will certainly satisfy the progressing needs of clients. As these trends evolve, they will certainly redefine the landscape of engineering remedies in the foundry field.

Sustainable Manufacturing Practices

As sectors increasingly focus on environmental duty, lasting production methods within shop solutions are ending up being necessary to modern-day design remedies. These techniques focus on minimizing waste, minimizing energy intake, and using environmentally friendly products throughout the production process. By executing techniques such as recycling scrap steel and maximizing melting processes, foundries can notably decrease their carbon impact. Additionally, the fostering of life process assessments enables makers to evaluate the environmental impact of their products from creation to disposal. Collaborating with distributors dedicated to sustainability even more boosts the performance of these campaigns. Ultimately, accepting sustainable production not just aligns with global environmental objectives but likewise cultivates advancement and competitiveness in the quickly advancing engineering landscape.Automation and Smart Technologies

While several sectors are embracing technological developments, foundry services are experiencing a significant improvement with automation and wise technologies. The integration of robotics and automated systems enhances manufacturing effectiveness, lowers human error, and accelerates the manufacturing process. Smart technologies, such as IoT and AI, enable real-time surveillance and predictive maintenance, which optimize operational efficiency and lessen downtime. These innovations facilitate data-driven decision-making, permitting foundries to react quickly to market needs and boost item top quality. Furthermore, automation lowers labor costs and boosts work environment safety and security by taking care of dangerous tasks. As foundry services remain to take on these developments, they are poised to redefine design remedies, bring about increased competition and sustainability in the manufacturing field.Personalization and Versatility Trends

Emerging patterns in foundry solutions progressively emphasize modification and adaptability to fulfill special customer demands. This shift mirrors a more comprehensive need for customized engineering solutions that adapt to details project demands and industry standards. Business are buying sophisticated innovations, such as additive manufacturing and digital modeling, allowing them to create customized elements efficiently and cost-effectively. Consequently, shops are moving away from one-size-fits-all strategies, offering clients the capacity to customize styles and materials in real-time. Furthermore, partnership between engineering teams and factory services is coming to be a lot more integrated, cultivating development and accelerating time-to-market. This fad not just boosts product performance yet additionally supports sustainability by lessening waste via specific manufacturing processes.Often Asked Inquiries

What Are the Normal Prices Connected With Shop Services?

Regular expenses associated with foundry solutions include material expenses, labor fees, devices use fees, and overhead costs - Aluminum Foundry. These expenses can vary commonly based on job complexity, quantity, and specific requirements of the engineering solution entailedHow Long Does the Foundry Refine Usually Take?

The foundry process usually takes anywhere from numerous weeks Aluminum Foundry to a few months, relying on elements such as intricacy, product requirements, and manufacturing volume, which can greatly influence timelines and overall job distribution.What Industries Benefit Many From Shop Services?

Industries such as automotive, aerospace, and construction benefit considerably from factory solutions. These markets depend on precision casting and metal fabrication to create complex components, enhancing product performance and operational effectiveness in their respective applications.What Accreditations Should Factories Possess?

Factories must have certifications such as ISO 9001 for high quality administration, ISO 14001 for ecological administration, and particular industry qualifications like AS9100 for aerospace or IATF 16949 for automotive, ensuring conformity and quality guarantee.Just How Do Foundries Make Sure Quality Assurance in Their Procedures?

Foundry services are essential in forming modern design solutions. As design disciplines have actually progressed, the duty of foundry solutions has changed greatly to satisfy advancing industry demands. As sectors increasingly focus on personalization and rapid prototyping, factory services have actually increased their abilities, guaranteeing they remain vital contributors to the engineering landscape. As industries significantly prioritize environmental obligation, sustainable manufacturing techniques within shop services are ending up being necessary to modern design remedies. Additionally, collaboration in between engineering groups and factory solutions is ending up being much more incorporated, fostering technology and increasing time-to-market.

Report this wiki page